Digital Transformation Technology & Solution Provider

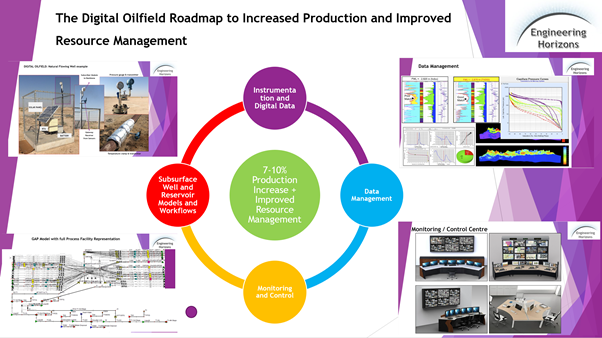

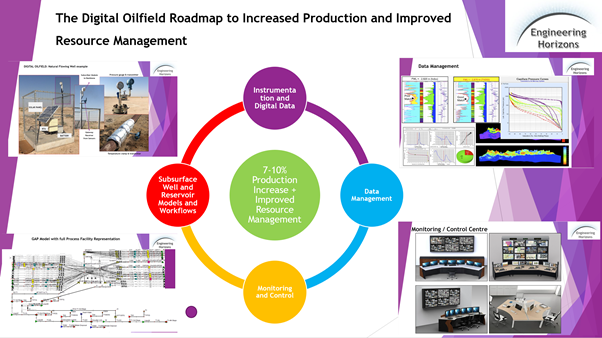

The deployment of the Digital Oilfield Solution involves several components: the installation of the instrumentation and connectivity system; a data management platform for both real-time and adhoc data; the development of engineering models and workflows; an Exception-Based Surveillance engine (EBS) and a friendly user interface integrating the entire system.

Optimization and Automation of tasks and routines that Petroleum Engineers normally execute can now be done through engineering workflows. These workflows are executed at specified time intervals. This increases the accuracy and reliability of the routines as real-time data is used to feed the calculations.

Surveillance by Exception: The principal behind Surveillance by Exception is that important information is brought to the users attention ahead of less important data. Due to the large size and number of wells in most oilfields, implementing surveillance by exception is a key feature. Indeed this becomes more important with many hundreds of wells producing and injecting continuously .

Optimization and Automation of tasks and routines that Petroleum Engineers normally execute can now be done through engineering workflows. These workflows are executed at specified time intervals. This increases the accuracy and reliability of the routines as real-time data is used to feed the calculations.

Surveillance by Exception: The principal behind Surveillance by Exception is that important information is brought to the users attention ahead of less important data. Due to the large size and number of wells in most oilfields, implementing surveillance by exception is a key feature. Indeed this becomes more important with many hundreds of wells producing and injecting continuously .